MPCA awards $10,000 Green and Sustainable Chemistry Prize to company focused on carbon capture

In the field of carbon sequestration — the removal of carbon dioxide from the atmosphere to prevent it from making the planet less livable — what matters most is how long the carbon can be put away and how much that’ll cost. For its answers to both of those questions, Eden Prairie-based Carba took home the MPCA’s 2023 Green and Sustainable Chemistry Prize.

“It’s a big deal how permanent the carbon removal is when drawing it out of the atmosphere,” says Al Innes, who served as one of the judges on the panel that presented the award to Carba. “We learned how they can put carbon out of reach for years and years.”

Those judges also learned how Carba has pioneered a low-cost method that makes its business viable and that uses much less energy than other carbon sequestration technologies. All that Carba really had to figure out was how to incorporate photosynthesis — the work that trees and plants already do — into its own process.

Confronting the entropy penalty

Carba began just a couple of years ago when entrepreneur and University of Minnesota graduate Andrew Jones, alarmed by climate change caused by added carbon dioxide in the atmosphere, started to look into how to subtract that carbon dioxide. He sat down with U of M chemical engineering professor Paul Dauenhauer, who had become his business partner and friend, to figure out why investors around the world were throwing millions of dollars at carbon-capture solutions that might have made for good headlines due to their use of renewable energy but ultimately “didn’t have long-term viability and wouldn’t scale,” according to Linda Hofflander, Carba’s head of strategy and business development.

“We need to get emissions under control before the world warms by two degrees Celsius, so we have to solve the problem of carbon removal quickly,” Jones says. “The solutions have to be affordable and scalable. And if they’re biomass-based like ours, they should be mobile to go where the biomass feedstocks are.”

In a paper that Jones and Dauenhauer wrote with Jimmy Soeherman that appeared in the American Chemical Society’s journal, ACS Engineering, they describe the energy inputs used to draw carbon dioxide out of the air in direct air capture (DAC) processes as “entropy penalty.” They also point out how traditional DAC processes and existing DAC machinery that make use of specially engineered surfaces, fluids, or membranes that trap and accumulate carbon dioxide pay high entropy penalties.

In theory, it shouldn’t take too much energy to capture carbon dioxide, the three wrote, but in practice, inefficiencies in existing DAC systems mean it can take from 1,600 to 18,000 kilowatt hours of energy to extract a metric ton of carbon dioxide from the atmosphere.

“This ‘entropy penalty’ results in substantial operating and capital costs associated with the CO2-accumulating equipment,” they wrote. “A substantial amount of energy is required to drive DAC technologies, and that renewable energy would have a larger impact on CO2 reduction when used to replace coal power plants rather than power DAC processes.”

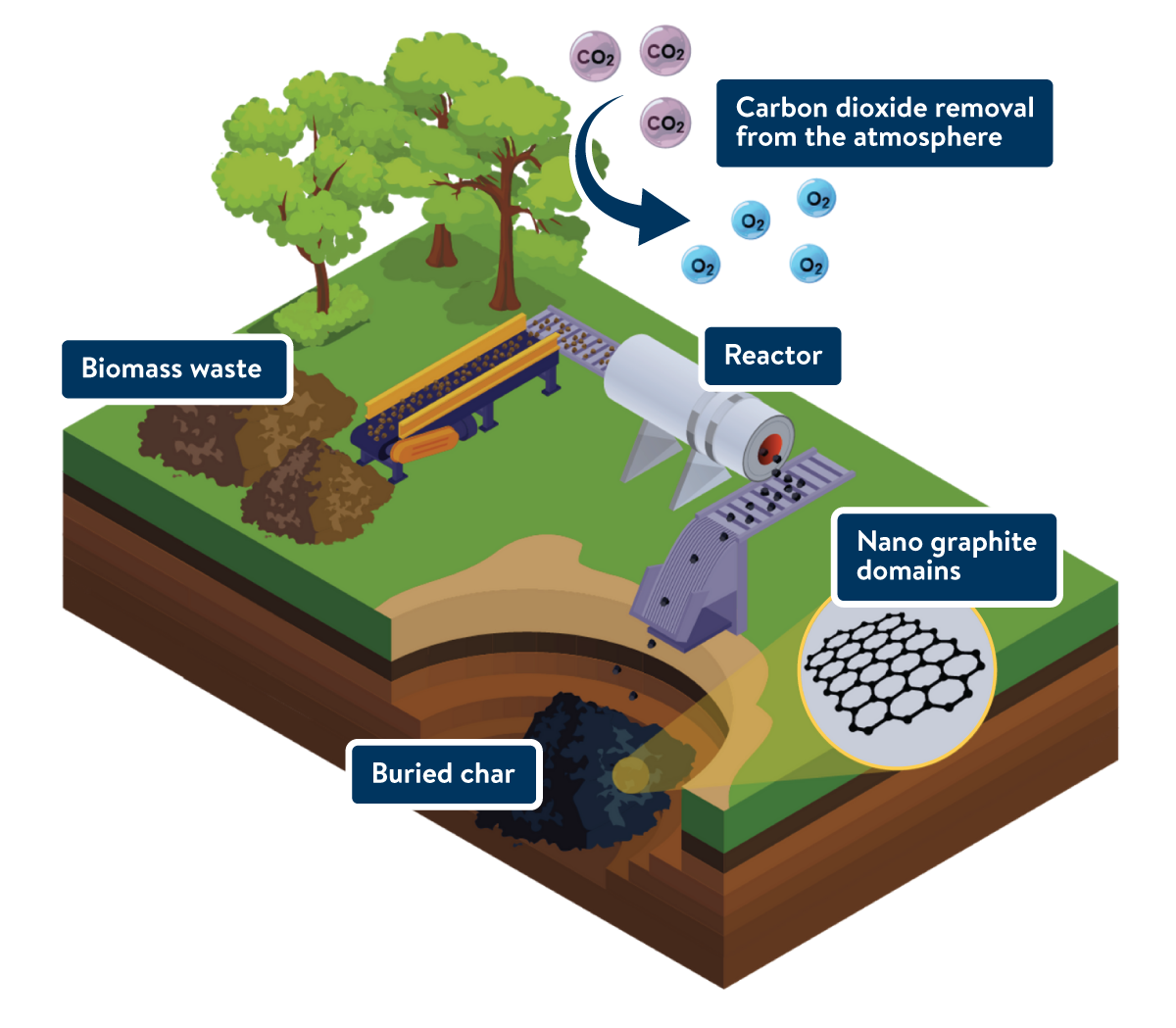

Instead, Jones and Dauenhauer propose “bypassing the entropy penalty” altogether by relying on trees and plants to perform DAC instead of machines, then converting the biomass from those trees and plants into solid carbon and burying that carbon deep underground.

As Jones and Dauenhauer argue, plants pay the entropy penalty by using sunlight to convert captured atmospheric carbon dioxide into biomass. Trees in particular “are the best direct air capture solution out there, so that’s where our process starts,” Hofflander says.

But plants and trees also die and decompose, releasing that captured carbon dioxide back into the atmosphere. To keep that carbon dioxide from doing any more harm, Jones and Dauenhauer took natural decomposition off the table and replaced it with a process called torrefaction.

A mobile solution

Torrefaction is a thermochemical process that relies on heat and the absence of oxygen to remove moisture, volatile gases, and all the microbes that lead to decomposition from biomass. What results is inert char, essentially purified carbon.

To make the char, Jones and Dauenhauer designed a proprietary torrefaction reactor, one that can take many different types of biomass, that a pickup truck with a fifth wheel hitch can tow from site to site, and that can use the volatile gases it removes from the biomass to help fire the reactor.

According to Hofflander, the prototype reactor spent a year in testing, during which Jones and Dauenhauer found that it uses just 70 kilowatt hours of energy per metric ton of carbon dioxide it captured. It can also take larger pieces of biomass as opposed to the pulverized biomass that other reactors need to use. Hofflander says the team expects to start operating a larger 45-ton reactor, capable of processing 15,000 tons of biomass per year, in June 2024.

In the meantime, the prototype reactor has moved to its first project site at the Burnsville Sanitary Landfill, where Specialized Environmental Technologies takes in large amounts of tree trimmings, trees damaged by emerald ash borers, and trees downed by storms — which Hofflander calls “low-value biomass” — for composting.

“There’s no other use for that biomass, so it will literally just sit there and rot,” Hofflander says. “By putting the reactor at that location, it’s just yards, not miles, to get all that biomass to the reactor.”

While Jones and Hofflander have investigated other biomasses, including nut shells and grasses, and alternative burial sites including mines and pits, the landfill and compost site in Burnsville work well as partners for this system of carbon capture, Hofflander says, due to odor and methane reductions.

Jones also says that the high-porosity char that Carba creates is perfect for capturing PFAS from landfill leachate water and preventing its release into groundwater and wastewater streams.

Carbon removal as a business

Carba, the business that Jones and Dauenhauer started to monetize their carbon capture ideas, won’t make money from selling or leasing the torrefaction reactors. Instead, it’ll bury the carbon to create carbon offset credits that it can then sell to organizations or individuals to compensate for emissions produced elsewhere.

“We think about it like reverse coal mining,” Hofflander says. “Other solutions that are claimed to be permanent only have to meet a minimum threshold in the voluntary market of 100 years, but ours will last for more than 1,000 years.”

She says that they’ve considered some other revenue streams, including selling the carbon for use in concrete, asphalt, steel, or rubber, “but we’re so laser focused on removal right now. Our long-term goal is to remove 1 billion tons of carbon by 2035, which means we need to get thousands of reactors running as quickly as possible — 7,000 reactors is the goal.”

The $10,000 prize that came with the Green and Sustainable Chemistry Prize that the MPCA awarded to Carba at the University of Minnesota Carlson School of Management’s MN Cup competition in September — along with the $85,000 prize that came with winning the MN Cup overall — will help Jones and Dauenhauer with that goal.

“We sponsor the award to try to stimulate more sustainable chemistry activity and get more buzz about solutions to the toxicity issues we’re facing,” Innes says. “This is the second year that Carba applied, and they’d made progress on the business side that makes them seem more viable. According to their figures, they have the lowest input and a lower cost to produce per unit of carbon removal. These are all good things.”

By no means does Carba see carbon capture and the selling of carbon offset credits as the only approach to solving the climate crisis, Hofflander says.

“We need every solution now, starting with fewer emissions, to reduce our carbon footprints,” she says.

But as Jones and Dauenhauer noted in their paper, carbon capture and burial are still necessary on top of reducing emissions to reverse more than a century’s worth of carbon dioxide emissions lingering in the atmosphere. If that carbon capture process can be made cheaper and more effective, then that’s all the better for the fight against climate change.

The MPCA’s Green and Sustainable Chemistry Prize will return for the 2024 MN Cup as the Sustainable Chemistry Prize.