Each tree that finds its way to Wood from the Hood’s warehouse in the Seward neighborhood of Minneapolis has a story. In fact, every wooden plank in the warehouse is marked with the ZIP code of where the tree once grew so customers know where their wood comes from. That lumber makes its way into many different products, from cribbage boards to home improvement projects.

Before places like Wood from the Hood existed, the trees that produced this lumber might’ve been destined for the burn pile. Instead, this “urban wood” — or wood salvaged from cities, suburbs, and towns — has found value, keeping woodworkers from depending just on traditional lumber harvests.

There isn’t anything wrong with the quality of the lumber from these urban trees. Urban wood itself is a growing issue in Minnesota because of the sheer quantity of trees coming down throughout the state for reasons like severe weather, urban expansion, and most notably, the emerald ash borer.

The pest that won’t give it a rest

The emerald ash borer was first discovered in Minnesota in 2009 and has been wreaking havoc on ash trees around the state ever since. After Dutch elm disease brought down a slew of trees in the 1970s and 1980s, they were replaced by ash trees, creating a monoculture in many cities and making the trees vulnerable to pests and disease.

The little green bug has caused quite a stir, damaging trees by boring into bark crevices, laying their eggs, and burrowing into the tree once they hatch. The bugs feed on the trees’ tissue under the bark, eventually killing the tree.

According to a 2022 wood waste study in the Twin Cities, by 2028, more than half a million tons of wood waste will be processed in the Twin Cities alone. The general consensus for ridding the area of emerald ash borer is to cut down infested trees to prevent the spread to other trees. That leaves cities, towns, and suburbs with large quantities of fallen trees that need somewhere to go.

Simply burning all this wood would lead to tons of carbon being released into the atmosphere and leaving them out to rot isn’t an option. To help decide the fate of many urban trees, the MPCA has convened a wood waste stakeholder group comprised of private businesses, nonprofits, state government agencies, counties, and cities that will improve the market for urban wood.

The wood waste hierarchy

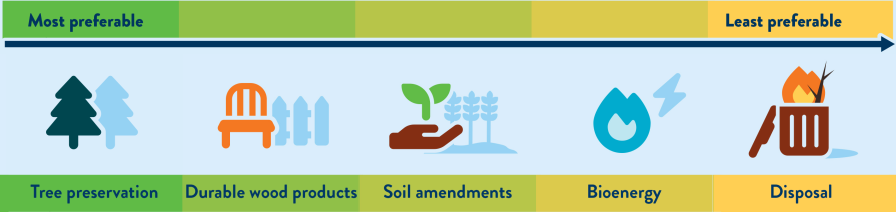

Of the many disposal options for wood waste, some are more desirable than others. The wood waste hierarchy provides a guide for the best disposal options for wood waste based on methods that range from the most to least environmentally friendly.

At the top of the list is tree preservation. Treating diseased trees and planting a wide variety of trees helps prevent disease. The issues seen with the emerald ash borer resulted from planting the same types of trees.

At the bottom of the list is open burning, with smoke and debris going directly into the air and posing a fire risk.

“This is something we really want people to move away from,” said Jon Klapperich, a wood waste specialist at the MPCA. “Still, hundreds of thousands of tons of wood are burned, just to get rid of it, resulting in the release of carbon.”

Somewhere in the middle of the hierarchy are a couple of different disposal solutions, like sustainable aviation fuel. Wood can be processed to create biomass, which is used for a low-carbon biofuel for airplanes.

According to Klapperich, we have the technology to convert wood waste into aviation fuel. While it isn’t a cheap investment for airlines, Delta and Sun Country have shown interest.

“We’re still in the early stages of this option,” Klapperich said. “There is a possibility that in five years we will start to see more wood waste being turned into aviation fuel.”

Another middle-of-the-road option is biochar, a charcoal-like substance that can be added to soil to improve soil health, store carbon, and filter out pollutants.

One of the more preferable options for dealing with urban wood involves creating durable wood products like furniture, building materials, and wooden décor. This area allows Wood from the Hood to make a huge difference in converting wood “waste” into high-quality furniture that can last a lifetime.

Wood from the Hood

Owners Rick and Cindy Siewert had the idea to start Wood from the Hood after losing an old ash tree from their backyard. Coming from a family cabinetry business, the Siewerts knew that the ash tree and many like it still had more to offer than fodder for the landfill, so they set out on a mission to share the potential of urban wood.

“Typically, people come into our store looking for something different,” Rick Siewert said. “We have some staples like maple, white oak, and cherry, but we try to talk to them and educate them about the different woods available.”

Wood from the Hood has been able to utilize the abundance of ash in new ways, like thermally modifying the ash, giving it a chemical-free level of protection, making the wood suitable to be used outdoors.

“The color is really cool, too,” Siewert added.

They typically source their wood from the Minneapolis Parks Board, which has an idea of what trees need to come down, especially if the board plans to cut down ash trees before they can spread the emerald ash borer. Sometimes local arborists provide lumber; at other times the shop gets something completely unexpected, like the time Siewerts received an old mahogany tree from the Marjorie McNeely Conservatory. “You can always do something with the wood, and we’re one of those uses here,” Siewert said.

From dining room tables to Christmas ornaments, Wood from the Hood finds ways to keep wood from going to waste.

Any scraps they cannot create usable products with go in a wood grinder to be sent to Dakota Energy to be burned as fuel. A few years back, Siewert had a local mushroom grower who would come to him for wood chips to help grow their mushrooms.

Because urban wood isn’t like traditionally harvested lumber, it can present a few challenges. The main one is excess metal, often found in the urban trees from people putting nails, screws, staples, hooks, and fencing in trees. The metal from these trees can damage saw blades and make processing the wood more time-consuming and expensive.

Wood from the Hood detects metal in the lumber before processing it, though sometimes it can create a stain in the wood from metal upstream in the lumber. Sometimes, these imperfections are just what people want.

Those imperfections can include the serpentine pattern left behind by the emerald ash borer, which many customers feel gives the wood character, according to Siewert.

“We dry all of our wood in a kiln and bring it up to a sterilization temperature to kill any bacteria or bugs in the wood,” Siewert said. “So, it’s something you don’t have to worry about.”

Perhaps what Siewert sees as the biggest draw of urban wood comes from the story behind it. It might be the pattern left behind by the beetle or the deep hues left behind from dried urban wood from a walnut tree. Each tree is unique and from somewhere that means a lot to a customer.

“People come in because they’re looking for something different and local,” Siewert said.

The shop uses a tracking system called AncesTREE that has information about where the tree was harvested, when it was harvested, and how much carbon is stored in the wood.

Approximately 400,000 pounds of carbon are stored in the trees in Wood from the Hood inventory, carbon that otherwise might have been released into the atmosphere through unnecessary burning.

The wood waste stakeholder group wants to keep looking for new ways urban wood can be used and support other local wood waste recovery locations.

This year, the MPCA distributed approximately $1.4 million in grants to eight organizations committed to preventing wood waste through tree preservation or wood reuse: East Phillips Neighborhood Institute, Great River Greening, Rainbow Treecare, River Bend Nature Center, Storm Trees, Tree Trust, the city of Plymouth, and Washington County.

These projects span across the wood waste hierarchy, investing in biochar production, tree preservation, wood waste recycling, and durable wood products.

The wood waste problem in Minnesota will continue to grow over the next few years, but solutions are also expanding. For now, people like Rick Siewert show that urban wood can have another life, and its story doesn’t have to end in the burn pile.

“People like having that connection,” he said. “It’s all about the story.”