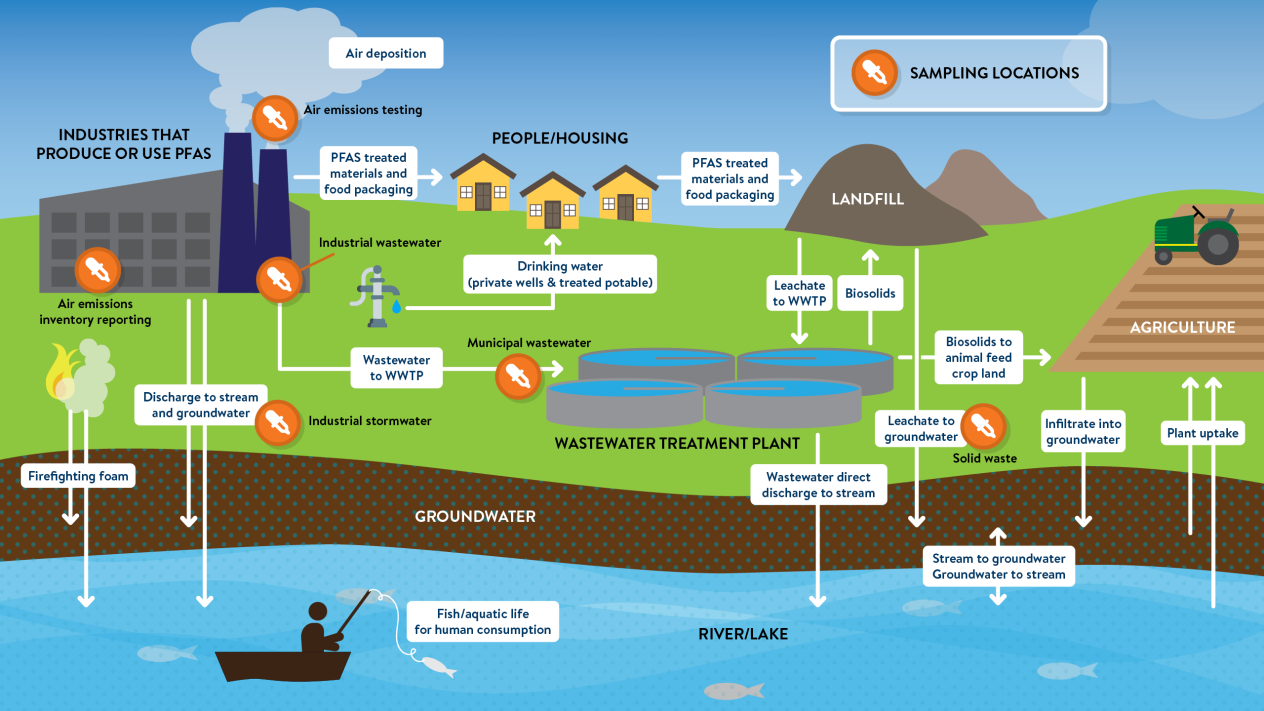

Per- and polyfluoroalkyl substances (PFAS) exist just about everywhere due to their extensive use in many products and manufacturing processes. To determine exactly how PFAS pollution becomes so widespread in Minnesota, the MPCA spent the last two years looking for the “forever chemicals” in groundwater near landfills, downstream of factories, and even in snow on rooftops.

The agency's report on its PFAS monitoring plan, which it released today, describes where the MPCA has found PFAS so far and uses that information to identify opportunities to avoid costly clean up, manage existing pollution, and protect human health.

“Given the number of potential PFAS sources in Minnesota, it was always going to be an ambitious project,” says MPCA PFAS coordinator Fawkes Char. “MPCA staff, contractors, local government partners, and facility partners have collected more than 600 samples from locations where PFAS pollution would likely be found, with more samples yet to come. Collaboration with the private sector and local governments have made this effort possible.”

PFAS might be best known to consumers for their use in nonstick cookware and lightweight raincoats, but the chemicals are also used in thousands of manufacturing processes and other products. New state laws will prevent PFAS pollution by phasing out nonessential PFAS use in Minnesota by 2032, but due to these chemicals’ current widespread use and longevity, identifying how they enter and move through the environment is important to reducing or removing these chemicals. The monitoring plan is part of Minnesota’s interagency PFAS Blueprint to prevent, manage, and clean up PFAS pollution.

“We’re grateful to everyone at the participating sites for their role in the PFAS monitoring plan. Hundreds of people were involved and helped us gain a better understanding of PFAS pollution,” says MPCA assistant commissioner Dana Vanderbosch. “This means we can better protect human health and the environment from PFAS. Sharing the initial findings helps the public understand how monitoring plays a critical role in our work and how we will put what we learned to work for Minnesotans.”

Monitoring takes a group effort

The report highlights how five MPCA permitting program areas implemented the PFAS monitoring plan. Each had unique challenges and findings:

- The air program got particularly creative about sampling techniques at some industrial facilities selected for sampling. “We don’t have an affordable way to directly sample air emissions for PFAS at many facilities, but we do know that snow near a vent or stack can capture PFAS being emitted,” says MPCA’s research scientist Derek King. “So, weather permitting, we collected snow samples, which meant being on rooftops in tricky conditions.” Not all results are back from the air program. The information from emissions inventory, stack tests, and snow sampling will help identify air sources of PFAS and shape a new rule requiring toxic air emissions reporting in the Twin Cities metro area by April 1, 2027.

- The industrial stormwater program asked regional airports, automotive shredding facilities, and metal finishers to sample areas where PFAS may be released through stormwater. Like many other facilities, airports, automotive shredding facilities, and metal finishers are known to use or have PFAS as a part of their operations. Some PFAS were detected at almost every facility, while other types of the chemicals were rarely detected. Source and exposure reduction plans are being developed at facilities with higher PFAS levels. The results will also help shape future permitting decisions. “The facilities we worked with understand the importance of getting ahead of PFAS issues,” says MPCA environmental specialist Brittany Aubol. "With these partnerships and the next steps we’re planning together, I am optimistic about reducing PFAS in the environment."

- The industrial wastewater program tested wastewater from facilities that have likely used PFAS based on the products they make. For instance, manufacturing semiconductors is known to involve PFAS, so the MPCA included that type of facility. Partial results are back from 12 facilities involved in seven kinds of industry. PFAS were detected at facilities, which are expected to use the information to reduce PFAS in wastewater discharges. The testing helped identify some sources of PFAS in Minnesota. Still, more testing is needed to understand the universe of industrial PFAS sources fully. The program will work to implement a PFAS permitting strategy to address the need.

- The MPCA’s solid waste and municipal wastewater programs are similar in that the landfills and municipal wastewater treatment facilities both have the challenging work of managing the wastes that we all produce. These sites don’t make or use PFAS, but PFAS-containing materials often make their way into the trash or down the drain.

- Like other program areas, strong partnerships were essential for the municipal wastewater program. “Minnesota’s wastewater treatment facilities recognize the importance of understanding where PFAS may be entering the environment,” says MPCA municipal PFAS coordinator Stephanie Lyons. “The partnerships that have been established between the MPCA and municipal facilities inspired 83 wastewater treatment facilities to participate in the MPCA’s effort to start to understand PFAS in wastewater. These facilities are also continuing work with the MPCA and local industries to identify potential sources of PFAS entering the wastewater collection system and to reduce PFAS being received in wastewater treatment systems.”

- The solid waste program tested groundwater near landfills to determine whether PFAS were present. “Since the wastes in these landfills contain PFAS, gathering data from the surrounding groundwater was important,” says MPCA hydrologist Laura Pugh. “We will use this data to continue to initiate changes to prevent groundwater contamination. It will also help us with future permitting decisions. Our landfills are critical components of our waste management system, so preventing PFAS in the products we throw away will be the best way to help landfills remain protective.”

Prevention will also make liquids removed from landfills, called landfill leachate, easier to manage. Follow-up is already underway at a few sites where PFAS levels in groundwater are above levels set by the Minnesota Department of Health and located near private drinking water wells. No community water supplies are believed to be impacted at this time.

“Although we’re expecting more data in the coming months, we’ve already learned so much more about potential sources of PFAS in the waste stream and the environment,” Char says. “We’re moving work forward to identify and implement actions to address those sources. Implementing the PFAS monitoring has been a massive lift. We appreciate the efforts of everyone involved.”